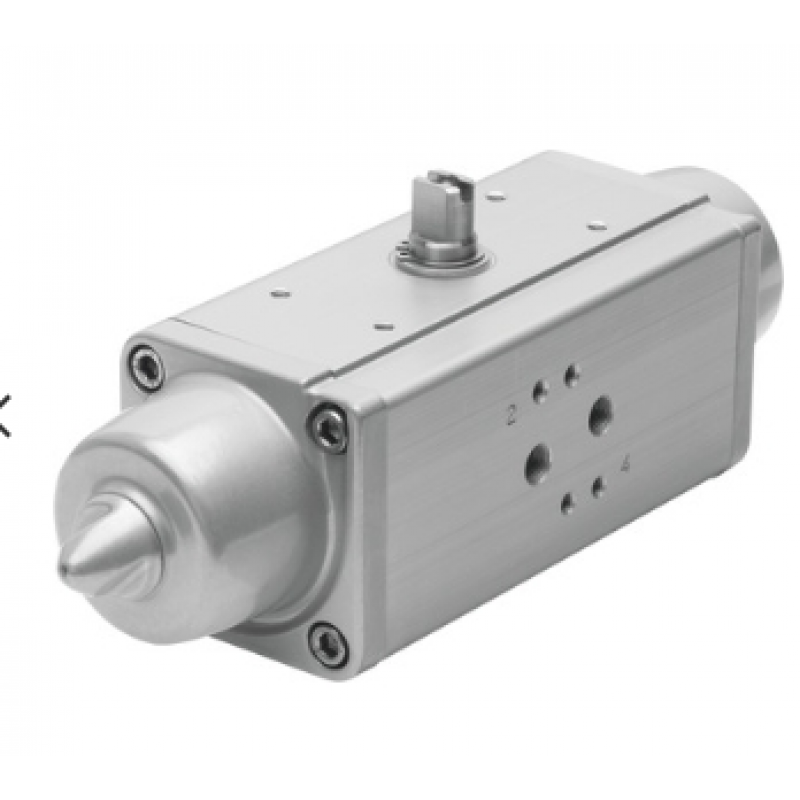

Product data sheet

Valve driver specifications

0053

Flange hole type

F05

F07

Swing angle

90 deg

End position adjustment range of 0 °

-1 deg ... 9 deg

Terminal position adjustment range at rated swing angle

81 deg ... 91 deg

Axis connection depth

19.3 mm

Explanation of end position adjustment range

One end position is optional and adjustable

The joint meets the standard

ISO 5211

buffer

Unbuffered

Installation location

Optional

Working mode

Single acting

Structural characteristics

Fork shift system

position detection

nothing

Turn off direction

Close Right

Symbol

00991266

The valve interface meets the standard

VDI/VDE 3845 (NAMUR)

Security Integrity Level (SIL)

Reaching SIL 2 low demand mode

Supply pressure of spring strength

0.56 Mpa

Supply pressure of spring strength

5.6 bar

working pressure

0.56 Mpa ... 0.84 Mpa

working pressure

5.6 bar ... 8.4 bar

Rated working pressure

0.56 Mpa

Nominal working pressure

5.6 bar

Maximum swing frequency at 6 bar

1 Hz

CE certification (see declaration of conformity)

Compliant with the EU Explosion Protection Directive (ATEX)

CE marking (see declaration of conformity)

According to the UK EX directive

explosion-proof

Zone 1 (ATEX)

Zone 2 (ATEX)

Zone 21 (ATEX)

Zone 22 (ATEX)

Certificate issuing authority

German Technical Supervision Association (T Ü V Nord) 212170801

ATEX gas category

II 2G

ATEX Dust Category

II 2D

Gas explosion-proof and flame-retardant type

Ex h IIC T6...T3 Gb X

Dust proof, explosion-proof, and flame-retardant types

Ex h IIIC T85°C... T200°C Db X

Explosion proof ambient temperature

-20°C <= Ta <= +60°C

Working medium

Compressed air, in accordance with ISO 8573-1:2010 [7:4:4]

Description of Work and Pilot Media

Can work with lubricating medium (must continue to work with lubricating medium thereafter)

Corrosion resistance grade CRC

3- High corrosion resistance

Paint Wetting Defect Substance (PWIS) Compliance

VDMA24364-B1/B2-L

ambient temperature

-20 °C ... 80 °C

Torque at nominal working pressure and 0 ° swing angle

53 Nm

Torque at nominal working pressure and 50 ° swing angle

26 Nm

Torque at nominal working pressure and 90 ° swing angle

35 Nm

Torque Description

According to the specifications for installing flanges and couplings, the working torque of the driver shall not exceed the maximum allowable torque listed in ISO 5211.

Spring reset torque at 0 ° swing angle

35 Nm

Spring reset torque at a 50 ° swing angle

26 Nm

Spring return torque at 90 ° swing angle

53 Nm

Spring strength

four

Air consumption per cycle at 6 bar, 0 ° - rated swing angle -0 °

2.1 l

Product weight

3000 g

Axis interface

T17

Pneumatic interface

G1/8

Material Description

RoHS compliance

Lid material

Refined aluminum alloy

Sealing material

FPM

NBR

PUR

Shell material

Refined aluminum alloy

Screw material

High alloy steel

Axis material

High alloy steel

Number axis material

one point four three zero five