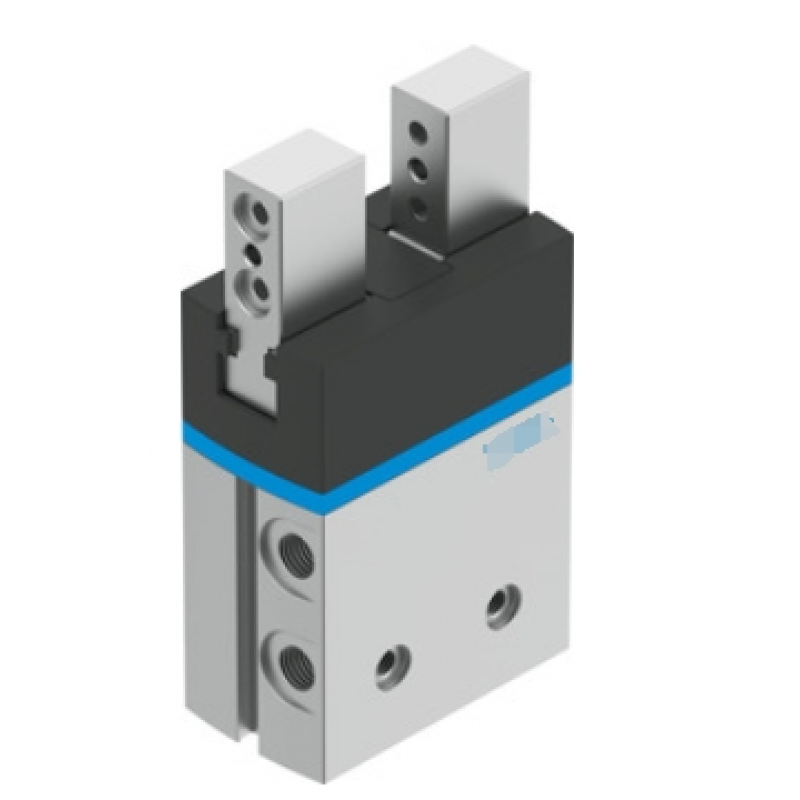

Product data sheet

Specifications

twenty-five

The stroke of each gripper gripper

7.5 mm

Maximum replacement accuracy

≤0.2 mm

The maximum gap ax and ay between swinging claw hands and gripping claws

<0.5 deg

Maximum gripper gap Sz

<0.02 mm

Rotational symmetry

≤0.2 mm

Repetitive accuracy, claw hand

<0.02 mm

The number of claws held by the gripper

two

driving system

Pneumatic

Installation location

Optional

Working mode

Double action

Claw function

parallel

Claw force backup

nothing

Structural characteristics

Handle

Forced pilot work movement sequence

guide

Sliding bearing guide rail

position detection

By proximity switch

Symbol

00991894

working pressure

0.2 Mpa ... 0.8 Mpa

working pressure

2 bar ... 8 bar

working pressure

29 psi ... 116 psi

The maximum working frequency of the gripper

2 Hz

Minimum opening time at 6 bar

48 ms

Minimum closing time at 6 bar

63 ms

Maximum mass of each external gripper gripper

350 g

Working medium

Compressed air, in accordance with ISO 8573-1:2010 [7:4:4]

Description of Work and Pilot Media

Can work with lubricating medium (must continue to work with lubricating medium thereafter)

Corrosion resistance grade CRC

1- Low corrosion resistance

Paint Wetting Defect Substance (PWIS) Compliance

VDMA24364-B2-L

Suitable for lithium-ion battery production

Do not use metals with copper content exceeding 5%. Exceptions: Printed circuit boards, cables, electrical plug connectors, and coils

ambient temperature

5 °C ... 60 °C

Total gripping force, open, 6 bar

500 N

Total claw force, closed, 6 bar

450 N

The gripping force of each gripper, open, 6 bar

249 N

Gripping force of gripper, closed, 6 bar

228 N

Moment of inertia

3.831 kgcm²

The maximum force Fz on the gripper, static

350 N

Maximum torque Mx of gripper, static

30 Nm

Maximum torque of the gripper My, static

30 Nm

Maximum torque of the gripper Mz, static

30 Nm

Lubrication intervals for guide components

10 MioCyc

Product weight

700 g

Installation method

or

Through internal threads and locating sleeves

Through through-holes and positioning sleeves

Pneumatic interface

G1/8

Material Description

RoHS compliance

End cover material

PA

Shell material

Hard anodized refined aluminum alloy

Claw grip material

High alloy stainless steel